Products

Ultraviolet absorbent

UV-531, UV-9, UV-P, 1798, UV-234, UV-326 and more.

Ultraviolet

absorbent |

|

Commodity name |

VIOCHEM UV-531 Details |

Commodity

name |

VIOCHEM UV-9 Details |

Commodity

name |

VIOCURE UV-P Details |

Commodity

name |

VIOCHEM 1798 Details |

Commodity name |

VIOCHEM UV-234 Details |

Commodity name |

VIOCHEM UV-326 Details |

Commodity name |

VIOCHEM UV-327 Details |

Commodity name |

VIOCHEM UV- 328 Details |

Commodity name |

VIOCHEM UV- 329 Details |

Commodity name |

VIOCHEM UV- 360 Details |

Chemical

Name |

Methanone,2-hydroxy-4-(octyloxy)-phenyl- VIOCHEM UV-531 |

Structure |

|

Applications |

The main application of UV-531 is in combination with

a HALS for the light stabilization of low density and linear

low density polyethylene as well as ethylene-vinyl acetate

copolymers for agricultural films. It can be used as well

as a UV barrier to protect combination with HALS UV-531 can

be used in high density polyethylene molded articles e.g.

in crates. |

Features/Benefits |

UV-531 is particularly suitable for thick films, typically >100um and |

Handling & Safety |

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Avoid continuous or

repetitive breathing of dust. Use only with adequate ventilation.

Avoid contact with eyes. Avoid release to the environment. Avoid

dust information and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2-Hydroxy-4-methoxybenzophenone VIOCHEM UV- 9 |

Structure |

|

Applications |

The main application of UV-9 is in combination with a HALS

for the light stabilization of low density and linear low density

polyethylene as well as ethylene-vinyl acetate copolymers for

agricultural films. It can be used as well as a UV barrier to

protect combination with HALS. UV-9 can be used in high density

polyethylene molded articles e.g. in crates. UV-9 also protects a number of other polymers against degradation caused by light exposure such us plasticized PVC and rubbers. |

Melting Point |

62-64℃ |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Avoid continuous or

repetitive breathing of dust. Use only with adequate ventilation.

Avoid contact with eyes. Avoid release to the environment. Avoid

dust information and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2-(2H-benzotriazol-2-yl)-p-cresol VIOCURE UV - P |

Structure |

|

Applications |

UV-P provides ultraviolet protection in a wide variety of polymers including styrene homo- and copolymers, engineering plastics such as polyesters and acrylic resins, polyvinyl chloride, and other halogen containing polymers and copolymers (e.g. vinylidenes), acetals and cellulose esters. Elastomers, adhesives polycarbonate blends, polyurethanes, and some cellulose esters and epoxy materials also benefit from the use UV-P. |

Features/Benefits |

UV-P features a strong absorption of ultraviolet radiation

in the 300-400 nm region. It also has a high degree of photostability

over long periods of light exposure. The high absorbance combined

with photostability and the ability to release absorbed energy

in non sensitizing ways make UV-P an effective stabilizer against

the effects of ultraviolet light. UV-P has Food Contact Approvals in rigid and flexible PVC applications for food, consumer care products and pharmaceuticals, preserving the package contents from the detrimental effects of light. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Protect skin. Prevent

contamination of the environment. Avoid dust formation and ignition

sources. For more detailed information please refer to the material safety data sheet. |

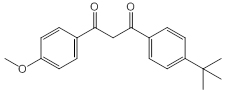

Chemical

Name |

Avobenzone VIOCHEM 1798 |

Structure |

|

Specification |

1,Appearance:White to light yellow crystalline powder;2,Melting Point:81~86°C;3,Assay:95.0%~105.0%;4,impurity:≤3.0%;5,weight loss:≤0.5%。 |

Application |

It is the mild anion emulsifier/stabilizers of W type, and easy to operate to shape. Mainly used in sunscreen, etc. it is suitable for PH3 ~ 9 range system. Can also be used as light stabilizer for Medicine cosmetics and perfume. |

Packing |

20、25KGS/CTN、DRUM;or according to the customer request |

Chemical

Name |

2-(2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethjyl)phenol VIOCHEM UV- 234 |

Structure |

|

Applications |

UV 234 is highly effective for polymers usually processed at high temperatures such as polycarbonate, polyesters, polyacetal, polyamides, polyphenylene sulfide, polyphenylene oxide, aromatic copolymers, thermoplastic polyphenlene fibers, where loss of UVA is not tolerated as well as for polyvinylchloride, styrene homo- and copolymers. Applications include molded articles, film, sheets and fibers. |

Features/Benefits |

UV 234 features low volatility, exceptional light absorbing

characteristics and good compatibility in various substrates.

This makes the product especially suitable for applications

characterized by high surface area, such as films and fiber.

It protects organic polymers as well as pigments from UV light,

improving and preserving the technical and visual performance

of such applications. UV-234 has world wide food contact Approvals in most polymers and is especially suitable in packaging applications for food, consumer care products and pharmaceuticals, preserving the package contents from the detrimental effects of light. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Aviod continuous or

repetitive breathing of dust. Use only with adequate ventilaton.

Prevent contamination of the environment.. Preven contamination

of the environment. Avoid dust formation and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

Phenol,2-(5-chloro-2h-benzotriazole-2-yl)-6-(1,1-dimethylehthyl)-4-methyl- VIOCHEM UV-326 |

Structure |

|

Applications |

UV-326 is especially suited for polyolefins, cold polyesters and wood lacquers. |

Features/Benefits |

UV-326 has a wide range of indirect food approvals in polylyolefins.

It has a low volatility at high temperatures and high resistance

to thermal degradation and can therefore be used without significant

loss or decomposition in the polyolefin compounding and molding

processes. In the use for the UV protection of Polyester resins, UV-326 does not form colored complexes with the metallic salts used for the curing process of these resins. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Avoid continuous or

repetitive breathing of dust. Use only with adequate ventilation.

Prevent contamination of the environment. Avoid dust formation

and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2,4-di-tert-butyl-6-(5-chlorobenzotria zol-2-yl)phenol VIOCHEM UV-327 |

Structure |

|

Applications |

UV-327 is a highly effective light stabilizer for a variety of plastics and other organic substrates. Due to its red-shifted UV absorption , it is particularly suited for use in the stabilization of polymers that are especially sensitive to long-wavelength UV radiation (e.g. polyurethanes, polyphenylene sulfide) and in certain applications where very low transmission of long-wavelength UV radiation is required (e.g. optical lenses). Its use is recommended in a variety of polymers and organic substrates, including acrylicpolymers, polycarbonate, polyesters, styrene homo-and copolymers, unsaturated polyesters, polyvinylchloride, polyolefins, polyvinylbutyral, elastomers, and adhesives. |

Features/Benefits |

UV-327 features strong UV absorption excellent compatibility in a wide variety of substrates, and moderately low volatility. It protects polymers as well as organic pigments from UV radiation helping to preserve the original appearance and physical integrity of molded articles, films, sheets, and fibers during outdoor weathering. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Avoid continuous or

repetitive breathing of dust. Use only with adequate ventilation.

Prevent contamination of the environment. Avoid dust formation

and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2-(2H-benzotriazol-2-yl)-4,6-ditertpentylphenol VIOCHEM UV- 328 |

Structure |

|

Applications |

UV-328 is a highly effective light stabilizer for a variety and plastics and other organic substrates. Its use is recommended for the stabilization of styrene homo- and copolymers, acrylic polymers, unsaturated polyesters, polyvinylchloride, polyolefins, polyurethanes, polyacetals, polyvinylbutyral, elastomers, and adhesives. |

Features/Benefits |

UV-328 features strong UV absorption low initial color, excellent compatibility in a wide variety of substrates, good solubility in plasticizers and monomers, and moderately low volatility. it protects polymers as well as organic pigments from UV radiation helping to preserve the original appearance and physical integrity of molded articles, films, sheets, and fibers during outdoor weathering. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and avoid unnecessary personal contact. Avoid continuous or

repetitive breathing of dust. Use only with adequate ventilation.

Prevent contamination of the environment. Avoid dust formation

and ignition sources. For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2-(2H-benzotriazol-2-yl)-4-(1,1,3,3,-teramethlbutyl)phenol VIOCHEM UV- 329 |

Structure |

|

Applications |

UV-329 is an effective light stabilizer for a variety of plastics and other organic substrates. |

Features/Benefits |

UV-329 protects polymers from UV radiation helping to preserve the original appearance and physical integrity of molded articles, films, sheets, and fibers during outdoor weathering. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and prevent contamination of the environment. Avoid dust formation

and ignition sources . For more detailed information please refer to the material safety data sheet. |

Chemical

Name |

2,2’-methylenebis(6-(2H-benzotriazol-2-yl)-4-1,1,3,3-tetramethylbutyl)phenol)VIOCHEM UV- 360 |

Structure |

|

Applications |

TINUVIN 360 applications include acrylic resins, polyalkylene

terephthalates, polycarbonates, modified polyphenylene ether or sulfide compounds, polyamides, polyacetals, polyolefins, styrenics, elastomers and high performance plastics. |

Features/Benefits |

TINUVIN 360 is particularly suitable for processing and aging

conditions where high loads, low volatility and good compatibility are required. The specific objective is to achieve high UV-screen performance and minimize sublimation through vents as well as prevention of deposits on molds, chill-rolls or calibrators. It can prevent exudation/crystallization on end-parts during manufacturing or exposure to high service temperatures. Such requirements are especially critical for complex moldings, fibers, sheets, twin wall sheets, thin films, adhesive layers and laminated or co-extruded semi-finished parts. Depending on equipment, processing conditions, and polymer types, TINUVIN 360 allows direct two-layer co-extrusion of sheets without the use of a neutral third top layer to prevent sublimation and/or deposits generated by the thin, highly UVA-loaded second layer. |

Handling & Safety

|

In accordance with good industrial practice, handle with care

and prevent contamination of the environment. Avoid dust formation and ignition sources. For more detailed information please refer to the material safety data sheet. |